Affected by the international political and economic situation, the global electronic industry's material supply will experience severe fluctuations in 2022. The high prices of key production materials for traditional lithium-ion batteries, such as cathode materials, will directly lead to the lithium battery industry turning its attention back to Na+ batteries.

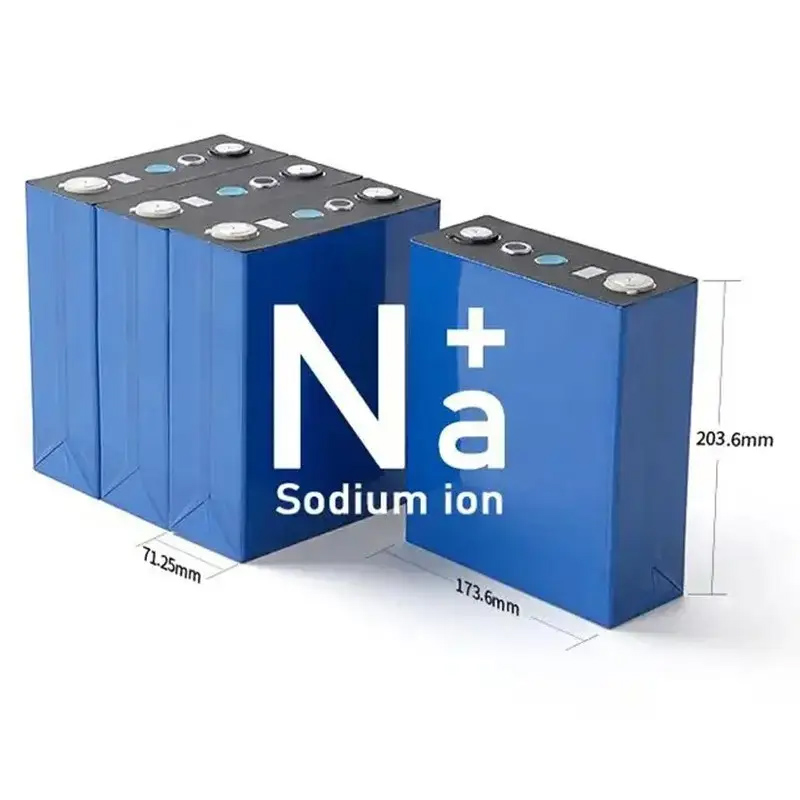

Based on the original technology, after more than two years of rapid development, driven by a series of manufacturers such as Zhongke Haina and CATL, square aluminum shell sodium-ion batteries have been mass-produced in 2024, and a new era is coming. However, there are still a series of problems that may hinder the large-scale commercial use of sodium-ion batteries. Several typical problems are as follows:

1. The energy density of sodium-ion batteries is still low

At present, the battery capacity of mass-produced sodium-ion batteries can basically only reach about 150Wh/kg, which is still a certain distance from the energy density of mass-produced LFP batteries, which is generally 165~200Wh/kg. Low energy density will inevitably lead to an increase in the volume of sodium-ion batteries with the same capacity, which directly leads to the inability of sodium-ion batteries to replace lithium-ion batteries with the same application.

2. The voltage range of sodium-ion batteries is relatively large.

The voltage application range of general lithium batteries is 2.0V~3.65V (LFP) or 2.5V~4.2V (NCM). However, since sodium-ion batteries have the ability to be discharged to 0V, the normal working voltage range can generally be set to 1.5V~4.0V, and the lowest voltage is significantly lower than that of lithium-ion batteries. Since general battery packs are used in series with multiple cells, the lowest total voltage is low, which will cause the normal working voltage range of the existing lithium-ion battery supporting inverter to be incompatible with that of sodium-ion batteries, and naturally cannot work normally. This further limits the smooth replacement and commercial evolution of sodium-ion batteries for lithium-ion batteries.

3. The charging and discharging characteristics of sodium-ion batteries are different.

Since the OCV curve of sodium-ion batteries is different from that of lithium-ion batteries, there is no voltage platform, and the overall OCV curve is relatively linear, which directly leads to the inability to use the existing BMS board directly, and the SOC evaluation algorithm must be modified according to the voltage and capacity characteristics of sodium-ion batteries.

4. The cost of sodium-ion batteries is still high

The cost is inevitably related to the scale of application. Due to the above factors 1-3, sodium-ion batteries cannot further expand their application scope, which slows down the application speed of sodium-ion batteries. Naturally, the cost of sodium-ion batteries cannot be effectively reduced, which seems to form a dead circle.

So, are these problems really unsolvable? Of course not!

The above 4 problems can be summarized into 1 point: technical problems. Whether it is a voltage problem or a SOC problem, it can be solved by BMS. The solution is: smart BMS. Of course, there is also the problem of energy density, which is not a problem in itself, because the battery factory is also constantly improving the energy density. I believe that in the near future, energy density similar to LFP will soon be achieved.

Smart BMS can integrate DC-DC modules, realize adjustable wide range of input and output voltages and integrate improved SOC algorithms, so that the direct use of lithium-ion battery supporting inverters can be realized, and even the application space of sodium-ion batteries can be further expanded.

Shanghai Enjie has always adhered to the concept of innovation. At present, our second-generation intelligent BMS is under development and will be available in the market in 2025. We hope that through our efforts, we can contribute to the early large-scale commercial use of sodium-ion batteries.

This is the last one.