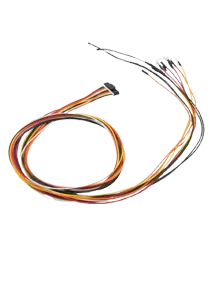

There are 2 types of cable in the battery PACK. We will provide these cables: 1. Connect BMS to cells, such as battery cell voltage&temperature sampling cable; 2. Connect BMS to panel interfaces, such as switch/LCD csreen/communication interfaces cables

Three BMS cable types are provided: Sampling cable, switch cable, LCD cable.

When selecting bms cables for your battery management system, it's essential to consider specific requirements to ensure compatibility and performance within your budget. Detailed specifications for bms cable types can be submitted to technical support for thorough confirmation and expert guidance. The right bms communication cable ensures reliable data transfer between system components, while understanding the appropriate bms cable name and cable bms specifications helps streamline the selection process for optimal system efficiency.

The bms cables are designed for immediate use, with finished cables that include wires and plugs for seamless integration into battery management systems. These bms communication cable solutions ensure reliable connectivity and efficient data transfer.

Cable customization can be carried out according to the actual needs of customers, including different characteristics such as plug type, brand, cable type, wire diameter, length, etc.

Battery Management Systems (BMS) rely on various specialized BMS cables to ensure safe and efficient operation. Knowing the different BMS cable types and their specific BMS cable names is essential for proper setup in lithium battery packs.

The sampling cable, commonly referred to as the balance or voltage sampling harness, is a key type among BMS cables. This multi-wire connector directly links the BMS to each individual cell in the battery pack. It typically features thin wires (such as 22-24 AWG) with a plug-in design, allowing the BMS to continuously monitor cell voltages and temperatures. This enables active cell balancing to prevent overcharging or imbalance issues. Correct sequential connection is critical for accurate data and battery safety.

The switch cable, also known as the on/off or power switch cable (sometimes called a cable BMS control wire), provides a simple external mechanism to activate or deactivate the BMS. This low-power option connects to a dedicated port, usually allowing a short press to turn the system on and a longer hold to power it off. It helps reduce parasitic drain during long-term storage.

The LCD cable connects an external display screen to the BMS, offering direct visual monitoring of essential parameters like state of charge, voltage, current, and faults—without needing a separate app. These pre-assembled BMS cables promote reliable integration and are particularly useful in applications such as solar energy storage, electric vehicles, and DIY battery projects.

For specific setups, additional options like a BMS communication cable may be required for data transfer to inverters or monitoring systems, depending on your BMS model. Always refer to your manufacturer's guidelines for compatible BMS cable types.

BMS cables handle data transmission by carrying signals from sensors and controllers to the central BMS unit. This function supports real-time monitoring and management of critical building systems, such as HVAC, lighting, and security, resulting in greater operational efficiency and faster system responsiveness.

Through power distribution, these cables supply electricity to essential BMS components, including sensors, controllers, and actuators. This ensures that all devices stay powered and operational, maintaining consistent communication and contributing to the overall reliability of the system.

The communication function allows BMS cables to facilitate data exchange between the central system and external devices or platforms, such as fire alarms, access control systems, and energy management solutions. This integration enables comprehensive building automation, with synchronized operations and rapid, coordinated responses to events or emergencies.

BMS cables are essential for integrating and connecting various building subsystems, enabling centralized monitoring, automation, and efficient operation across modern facilities.

BMS cables connect thermostats, temperature sensors, humidity sensors, and controllers to the central system. This integration allows precise management of heating, ventilation, and air conditioning, ensuring optimal indoor comfort while reducing energy consumption through automated adjustments.

These cables link lighting fixtures, occupancy sensors, and dimmers to the BMS. This setup enables automated lighting control based on occupancy, time schedules, or natural light levels, resulting in significant energy savings and enhanced user convenience.

BMS cables integrate access control devices, surveillance cameras, motion detectors, and alarm systems with the central BMS. This connectivity provides unified monitoring and rapid response capabilities, improving overall building security and safety management.

By connecting smoke detectors, fire alarms, and suppression system controls to the BMS, these cables ensure seamless integration. This allows for coordinated emergency responses, such as automatic shutdown of HVAC systems to prevent smoke spread or unlocking doors for safe evacuation.

BMS cables facilitate the connection of energy meters, power monitors, and controllable loads throughout the building. This enables comprehensive monitoring and optimization of energy usage, helping identify inefficiencies, implement demand response strategies, and achieve greater sustainability and cost savings.